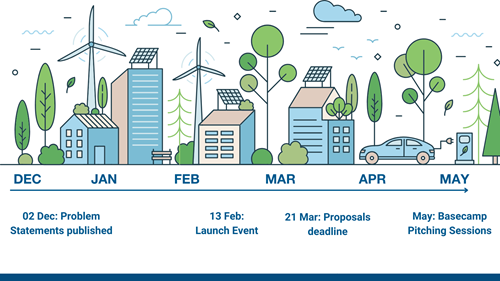

Energy Innovation Basecamp - Problem Statements 2025

Applications are now closed

We asked GB's Electricity and Gas Networks to share some of the specific, technical challenges they are facing, both in the short-term and as we progress through the Energy System Transition. Here, you can learn more about these network challenges.

Pick a theme below to anchor to correct section of page:

- Building Better, Faster and Safer

- Decarbonising Network Operations

- Maximising Use of Existing Infrastructure

Building Better and Faster

Modernising the design of planning, procurement and construction projects to deliver better, faster and more innovatively.

What is the problem?

How do we improve our riser replacement program including refurbishment making it safer, cheaper and less disruptive ?

Managing gas riser replacements in multi-occupancy buildings presents significant challenges, including:

- Scaffolding Requirements: Traditional methods often necessitate extensive scaffolding, leading to increased costs and disruptions for residents. Scaffolding installations must comply with safety standards and may involve notifying insurance companies.

- Access and Coordination: Gaining access to individual units can be challenging, especially when residents are unavailable, complicating scheduling and prolonging project timeline

- Safety and Compliance: Ensuring that new installations meet current safety standards, such as those outlined in IGEM/G/5 Edition 3, is critical. Compliance with regulations requires thorough planning and execution.

- Disruption to Residents: Riser replacement work can disrupt daily routines, particularly for vulnerable residents. Minimizing inconvenience is essential to maintain good relations and ensure safety.

- Technical Challenges: Replacing risers in older buildings may involve dealing with outdated infrastructure, requiring specialized solutions to integrate new systems effectively.

- Cost Management: Balancing the need for safety and compliance with budget constraints is a constant challenge. Cost-effective solutions are necessary to manage resources efficiently.

What are we looking for?

We are seeking new and creative innovative ideas that will drive innovation in improving how riser replacement is carried out from the replacement itself to surveying:

- Develop methods to minimize or eliminate the need for scaffolding to reduce costs and resident disruption.

- Develop solutions to efficiently gain access to individual units.

- Utilize materials and technologies that enhance the safety and longevity of gas riser installations while minimising noise, dust, and other disruptions during replacement activities.

What are the constraints?

Solutions must be:

- Regulatory Compliance: All solutions must adhere to existing safety regulations and industry standards, such as those outlined in IGEM/G/5 Edition 3.

- Technical Feasibility: Proposed methods should be applicable across various building types and compatible with existing infrastructure.

- Budget Limitations: Innovations must be financially viable within the constraints of allocated budgets.

- Time Efficiency: Solutions should aim for rapid implementation to reduce downtime and inconvenience to residents.

Who are the key players?

- Gas Distribution Network Operators (DNOs): Companies responsible for the maintenance and operation of gas distribution networks.

- Regulatory: Organizations like the Health and Safety Executive (HSE), Building Safety Regulator (BSR) and the Gas Safe Register

- Industry Associations: Institution of Gas Engineers and Managers (IGEM) that provide guidelines and best practices.

- Technology Providers and supply chain: Companies specializing in advanced repair materials and techniques, including robotics and non-intrusive repair methods.

- Academic and Research Institutions: Entities conducting research on innovative gas infrastructure maintenance solutions that could be applied to gas risers for multiple occupancy buildings.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

- Regulatory Frameworks: Aligns with safety and operational standards set by regulatory bodies, ensuring compliance with current legislation.

- Industry Standards: Adheres to guidelines such as IGEM/G/5 Edition 3, which outlines best practices for gas installations in multi-occupancy buildings.

Download full document here

Presentation slides here

Presentation video here

What is the problem?

Managing gas riser assets in multi-occupancy buildings presents significant challenges, particularly in minimizing service interruptions during maintenance and repairs. Traditional methods often necessitate gas supply cut-offs, adversely affecting residents, especially vulnerable individuals. The goal is to develop advanced live repair techniques that ensure safety, cost-effectiveness, and long-term durability while maintaining continuous gas flow.

With this complex asset, how do we expand beyond current repair techniques like heat shrinks and micro stop, that will reduce the need to cut off the riser?

What are we looking for?

We seek new and creative innovative ideas that will:

- Enable live maintenance and repair of gas risers without disrupting service to occupants.

- Utilize advanced materials, technologies, or methodologies to enhance repair efficiency and effectiveness.

- Ensure compliance with safety regulations and industry standards.

- Are scalable and adaptable to various building types and configurations.

- Prioritize the needs of vulnerable customers by minimizing inconvenience and potential hazards.

What are the constraints?

Solutions must be:

- Adherence to stringent safety standards is paramount to prevent hazards or future issues within the building.

- Techniques must align with industry standards and legal requirements, including those set by bodies like the Gas Safe Register in the UK

- Solutions should be applicable to various types of gas risers and compatible with existing infrastructure.

- Solution must be feasible in various environments, including areas with limited access or confined spaces, without causing significant disruption.

- Solution must be durable and effective to prevent any recurring issues and additional costs.

Who are the key players?

- Gas Distribution Network Operators (DNOs): Companies responsible for the maintenance and operation of gas distribution networks.

- Regulatory: Organizations like the Health and Safety Executive (HSE), Building Safety Regulator (BSR) and the Gas Safe Register

- Industry Associations: Institution of Gas Engineers and Managers (IGEM) that provide guidelines and best practices.

- Technology Providers and supply chain: Companies specializing in advanced repair materials and techniques, including robotics and non-intrusive repair methods.

- Academic and Research Institutions: Entities conducting research on innovative gas infrastructure maintenance solutions that could be applied to gas risers for multiple occupancy buildings.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

This problem statement builds upon existing policies and innovations:

- Regulatory Frameworks: Aligns with safety and operational standards set by regulatory bodies, ensuring compliance with current legislation.

- Industry Standards: Adheres to guidelines such as IGEM/G/5 Edition 3, which outlines best practices for gas installations in multi-occupancy buildings.

Download full document here

Presentation slides here

Presentation video here

What is the problem?

Before cable jointing takes place on any cable, it must be correctly identified. Signal injection identification techniques are used, but they rely on the roll of the cores within the cable. Paper Insulated Lead Covered (PILC) triple and double concentric cables cannot be positively identified using these methods as the cores are concentric and have no roll.

Currently to identify a triple concentric cable the method is as follows:

- Digging a larger joint hole to expose all cables in the immediate vicinity.

- Once all other cables have been identified, the remaining cable must be the concentric cable.

- This is then confirmed by digging back to an expected joint, requiring extra excavation work.

What are we looking for?

A method or tool to be able to identify a triple and double concentric cable without having to excavate for a positive identification.

What are the constraints?

The solution must:

- Must operate when the cable is energised to avoid supply interruptions.

- Provide an unambiguous identification.

- Avoid any form of “cross-talk” with other cables.

- Must also work with a dead cable. An AC supply may be available from a busbar.

The solution should:

- Simple to operate so it becomes “method of choice”.

-

- Portable as it needs to be carried into a joint hole.

Who are the key players?

This solution will be adopted by UKPNs frontline Network Operations staff. In gaining approval for the method, we will also work closely with our Health and Safety and Standards team to ensure it can be safely deployed.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

No

What else do you need to know?

N/A

Download full document here

Presentation slides here

Presentation video here

What is the problem?

To achieve a safe method of working UK Power Networks uses a four-pin earth nest – compared to a single pin earth - to achieve a 50Ω impedance for the circuit main earth (CME).

This value was established to ensure that a circuit breaker would trip when the CME is applied to the overhead line.

There have been a few occurrences where a point of isolation, involving a disc insulator, has failed and hasn’t fully de-energised the circuit, resulting in the circuit breaker tripping. The linespeople were not able to identify this due to the sensitivity of the voltage detector being used. Existing HV detectors detect down to 3.5kV.

We need a more sensitive HV voltage detecting device that can reliably detect the presence of voltage below 1kV avoiding circuit breaker operation.

What are we looking for?

A device to reliably carry out voltage detection tests below 1kVA with a more sensitive HV Voltage detector, or a innovator prepared to develop such a detector to an agreed specification.

What are the constraints?

The solution must:

- Attach to insulated rods using a universal head

- Provide a visible and audible warning in the event it detects votlage.

- Be fully waterproof.

Who are the key players?

This solution will be adopted by UKPNs frontline Network Operations staff. In gaining approval for the method, we will also work closely with our Health and Safety and Standards team to ensure it can be safely deployed.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

No.

What else do you need to know?

No.

Download full document here

Presentation slides here

Presentation video here - video starts from minute 17:00

What is the problem?

The LV network is increasingly important in delivering a reliable supply of power to homes and businesses as they decarbonise and adopt Low Carbon Technologies that they rely on. This means that knowing exactly where our assets are and what their specifications are is becoming more vital when responding to outages or planning and delivering network upgrades.

To provide a better service to our customers, we need a more accurate and complete database of our underground network that we currently have.

While the primary focus for this is the LV network, we would also like it to be scalable to higher voltages as required.

What are we looking for?

We are looking for a proposal that will be able to integrate new data into our existing GIS tool. It needs to be able to draw data from a variety of sources such as job sheets, wayleaves (?) and existing mapping as well as understanding likely dates of installation and asset types used at those times. This will allow us to make an assessment of the likely capacities and composition of the underground assets. Also having more accurate locations of our assets and having that mapped would be valuable

We can then use this to inform network development plans as well as effect faster repairs after faults.

What are the constraints?

The solution must be able to integrate with the existing GIS tool used by SSEN.

It must be able to draw data a from a variety of sources, some of which may be incomplete.

Who are the key players?

The key stakeholders for this problem sit within our DSO and Operational functions. Solutions will help with network planning, forecasting, flex procurement etc, as well as fault response.

We are open to applications from any innovator but currently see this sitting in a digital modelling environment.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

There are many projects looking at the LV network currently as the uptake of LCTs increases. These include projects such as Substation monitoring, LV Power Quality, Portable LV FPI, and RESOP. As far as we are aware this is the only project that is looking specifically at using historical records, with some field work input, to understand makeup and location of underground LV assets

What else do you need to know?

No.

Download full document here

Presentation slides here

Presentation video here - video start from minute 13:42

What is the problem?

Data gathering using drones has become a standard practice in electricity networks, particularly for overhead line inspections. This is due to their cost efficiency, time-saving capabilities, and improved data quality. However, the use of drones within substations is less common due to the higher complexity of the space and access restrictions. This gap presents an opportunity for development, with significant potential benefits in cost savings and data quality improvements in substation inspections.

What are we looking for?

Developing a drone that will be able to fly inside a substation autonomously. This would include the production of a set of drone requirements that will guarantee a safe use of those devices inside the substations.

What are the constraints?

- Civil Aviation Authority (CAA) regulations for drone flights

- Autonomous navigation and maintenance of safe distances from assets.

- Ability to take multiple photos of specific asset sites from optimal angles and positions.

- Adherence to SPEN security policies.

- Collaboration with data analytics companies to ensure optimal data quality.

Who are the key players?

TOs, drone developers, CAA, data analytics companies.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

No.

Download full document here

Presentation slides here

Presentation video here

What is the problem?

The lack of accurate asset information for UK energy networks has broad implications for operational efficiency, safety, regulatory compliance, risk management and the ability to adapt to future energy needs. Addressing the issue is crucial for maintaining service reliability through the transitions, reducing costs and supporting the broader transition to a more sustainable energy system. Throughout the energy systems transition, energy networks will be required to adapt their existing infrastructure. Accurate asset information is critical to integrating new technologies into the existing network, ensuring that future energy demands can be met while maintaining reliability and safety.

During operational activities networks need precise asset information to optimize resource allocation, streamline maintenance schedules and plan for future growth of infrastructure. Without accurate information, operators might waste resources on unnecessary work or miss opportunities for cost saving measures, eg predictive maintenance.

What are we looking for?

We are looking for solutions that can accurately predict and/or locate the positions of assets within the network. Currently the NUAR (National Underground Asset Register) project is working on depicting a large number of underground assets owners infrastructure data on their mapping site. The main reason behind this was to reduce the number of asset damages due to lack of available data or inaccurate data. However with this we would be looking for a solution that is less intrusive that can use artificial intelligence coupled with machine learning capabilities to more accurately predict the locations of assets. This can also be linked to more intrusive in field data where engineers or contractors have logged positions of such assets.

For this type of project it would start at a low TRL as currently there isn’t anything on the market, this would then be able to be developed with the networks inputs of asset data alongside, the assumptions that can be added into the system.

What are the constraints?

The key constraints with this will be the volume of the assets that are buried below ground and have no existing data on them, such a services splitting from the main line/pipe up to the property. In some cases this can be linked if the position of the main is known with the position of the meter on the property boundary.

The solution would ideally be a non intrusive solution that can be a desktop based review of the current network data that builds in assumptions to predict asset locations. Reducing the costs on staff attending site in person, but have the ability to add in the correct information if someone does attend site.

Who are the key players?

Gas Distribution Networks, electricity distribution networks and water companies, who all supply to customers.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

N/A

What else do you need to know?

Nothing further to add.

Download full document here

Presentation slides here

Presentation video here - video start from minute 20:20

What is the problem?

SPEN have committed through their Action Plan for Nature to be ‘nature positive for direct impacts by 2030’. This commitment and plan to get them involves taking steps to Identify, Plan, Measure / Value, Act and Transform the business, and assessing impacts on nature from existing infrastructure is part of this.

Bird strikes on overhead line (OHL) infrastructure pose significant challenges, including power outages, damage to equipment, and harm to avian populations. These incidents can lead to costly repairs, service interruptions, and negative environmental impacts. As such, there is a pressing need to develop and implement effective strategies to monitor, record, and prevent bird strikes on OHL infrastructure.

Key Challenges:

- Detection and Monitoring:

- Current OHL infrastructure lacks the capability to effectively detect and monitor bird activity in real-time.

- There is a need for reliable sensors and monitoring systems that can accurately identify bird presence and behaviour near power lines.

- Data Recording and Analysis:

- Existing systems do not adequately record data on bird strikes, making it difficult to analyse patterns and develop preventive measures.

- Implementing robust data recording and analysis tools is essential for understanding the frequency, timing, and locations of bird strikes.

- Preventive Measures:

- Traditional methods, such as bird diverters and reflectors, have limited effectiveness in preventing bird strikes.

Innovative solutions are required to deter birds from flying into power lines without causing harm to the birds or disrupting power transmission

What are we looking for?

- The primary objective is to identify and implement retrofitting solutions for existing OHL infrastructure that enhance the monitoring, recording, and prevention of bird strikes. This involves integrating advanced technologies and design modifications to create a safer environment for birds while ensuring the reliability and efficiency of power transmission

Potential Solutions include:

- Advanced Sensor Integration:

- Automated Data Recording:

- Innovative Deterrents:

What are the constraints?

The solution must:

- Develop specific recommendations and actions SPEN can implement on their networks to better record, avoid and reduce impacts on birds

- Solutions should aim to be as cost effective as possible. Details on the likely cost of implementing measure would be appreciated.

Who are the key players?

SPT, SPM, SPD, Local Authorities, Nature Scot, RSPB, Natural England, Specialist Companies, Startups, Local Communities.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

N/A.

What else do you need to know?

We would expect this study to be tailored to the UK context in which SPEN operates, taking consideration of the different bird species across SPENS operational areas and the differing characteristics.

Download full document here

Presentation slides here

Presentation video here

Decarbonising Network Operations

Considering the requirements of net zero commitments in every stage of project lifecycles, to reduce the emissions associated with present and future network operations.

What is the problem?

Environmental Impact of Reinstatement: How can we reduce the environmental impact of site reinstatement?

As networks, to ensure we maintain a safe and reliable network, we need to maintain, repair and/or replace our below ground assets. To do this, we generally have to break ground and excavate to carry out our activities, depending on the activity, this could be single/multiple excavations and/or trenches. We then have to make good the excavations through various backfill and reinstatement methods.

These reinstatement activities require considerations of type of materials, methods of delivery to site and the process (mechanical or manual) of backfilling, compacting and reinstating.

What are we looking for?

Backfill & Reinstatement techniques

As networks we already use standard approaches, but we are always looking for alternatives that drive lower environmental impact along with cost efficiencies and reduction to disruption.

Compacting Tools & Equipment

We already look to use tools & equipment that will ensure the relevant quality of reinstatement as well as to reduce our carbon footprint but again we are always looking for alternatives that do this, as well as being safe and effective for our teams to use.

What are the constraints?

Any new transport, materials, plant, tools and equipment introduced into our networks must meet all the relevant safety and engineering requirements for the relevant activity. Ease and speed of use is also important to ensure training burdens can be mitigated. For gas networks, any potential solutions need to meet future requirements and consider Methane, Hydrogen, Blended Hydrogen/Methane and Biomethane as gases within our networks. As with all Streetworks related activities, there are a number of requirements under NRSWA, TMA, SROH, Red Book etc that need to be considered.

Who are the key players?

This is mainly aimed at the distribution networks due to the nature and volume of excavations & reinstatements carried out in the public highways & footpaths but could apply to transmission.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

There have been many previous areas of work on backfill & reinstatement, low carbon tools and equipment but generally driven by cost efficiencies, productivity, quality improvements and reducing disruption rather than being to decarbonise our operations.

What else do you need to know?

N/A

Download full document here

Presentation slides here

Presentation video here

What is the problem?

Excavation Process: How do we make the excavation process zero emission?

As networks, to ensure we maintain a safe and reliable network, we need to maintain, repair and/or replace our below ground assets. To do this, we generally have to break ground and excavate to carry out our activities, depending on the activity, this could be single/multiple excavations and/or trenches.

These excavation activities generally require tools and techniques using mechanical excavation equipment that runs on diesel generators or from on board power in diesel or petrol vans.

What are we looking for?

Repair techniques

As networks we already use robotics to enable repairs such as CISBOT and STASS, but we are always looking for alternatives that drive cost efficiencies and reduction to disruption. (Gas only)

Tools & Equipment

We already look to use tools & equipment that reduce our carbon footprint but again we are always looking for alternatives that do this, as well as being safe and effective for our teams to use. (Elect & Gas)

What are the constraints?

Any new plant, tools and equipment introduced into our networks must meet all the relevant safety and engineering requirements for the relevant activity. Ease and speed of use is also important to ensure training burdens can be mitigated. For gas networks, any potential solutions need to meet future requirements and consider Methane, Hydrogen, Blended Hydrogen/Methane and Biomethane as gases within our networks. As with all Streetworks related activities, there are a number of requirements under NRSWA, TMA, SROH, Red Book etc that need to be considered.

Who are the key players?

This is mainly aimed at the distribution networks due to the nature and volume of excavations & reinstatements carried out in the public highways & footpaths but could apply to transmission.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

There have been many previous areas of work on robotic repairs, low carbon tools and equipment but generally driven by cost efficiencies, productivity and reducing disruption rather than being to decarbonise our operations.

What else do you need to know?

N/A

Download full document here

Presentation slides here

Presentation video here

What is the problem?

Construction sites are critical touchpoints for reducing environmental impact, yet are often linear practices where materials, resources, energy are not fully utilised. This model misses' opportunities to minimise waste, maximise resource efficiency and create a regenerative system where materials, energy and products are continuously reused and repurposed. To achieve net-zero goals and impact sustainability in the short term, the networks must reimagine its construction processes through the lens of the circular economy.

What are we looking for?

We are seeking new and creative innovative ideas that will drive innovation in sustainability and circular economy practices that are scalable, impactful and applicable in construction processes. Examples include:

- Decentralised resource recovery systems that repurpose resources like energy and materials at a local level.

- Digital Tools for Resource Optimization that monitors, predicts and optimises the use of resources like water, energy and materials in real time.

What are the constraints?

Solutions must be:

- Tangible Impact: Solutions with measurable outcomes that improve operational performance (e.g., percentage reduction in waste, CO₂ savings, or cost savings).

- Technology-Driven Approaches: Tools that enhance material tracking, enable reuse, or optimize waste management in innovative ways.

- Policy-Driven Models: Concepts that address regulatory compliance and create frameworks for circularity within construction projects.

Who are the key players?

Network Operations and Engineering Teams who will be responsible for implementing and adapting circular solutions within day-to-day workflows. Also, procurement and innovation teams will be key to support development and implementation,

Academia, Startups and Innovators who will provide disruptive solutions, technologies, or business models that can be integrated into existing systems and create new ones

End customer will be members of the public within local communities who will be impacted by construction, waste, and resource management practices.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

- Net-Zero Commitments:

- The UK’s legally binding commitment to reach net-zero emissions by 2050 (Scotland by 2045) directly influences the need for circular economy solutions.

- Policies like the Environment Act 2021 and Waste Framework Directive set waste reduction, recycling, and resource efficiency targets.

- Resource and Waste Management Policies:

- Regulations promoting extended producer responsibility (EPR) and waste prevention strategies provide frameworks for circular practices.

What else do you need to know?

N/A.

Download full document here

Presentation slides here

Presentation video here

What is the problem?

The current problem with GB energy networks and plastic waste during operational works is the widespread use of single use plastics in infrastructure installations and maintenance, such plastic fittings, plastic sheeting (eg visqueen), packaging for materials, cut offs and bypasses. These plastics are often not properly recycled and contribute to environmental pollution. Additionally despite growing awareness of sustainability, many companies still lack comprehensive strategies for reducing plastic waste, leading to an accumulation of non-biodegradable materials in landfill or the environment. Efforts to reduce the waste are hindered by cost, logistical challenges and limited industry wide adoption of sustainable alternatives.

What are we looking for?

To tackle to problem of plastic waste, the GB energy networks would be looking for solutions that covers the below:

-Adopting sustainable materials, by transitioning to biodegradable or recyclable alternatives, reducing the reliance on single use plastics

-Helping to improve the recycling protocols within operational processes to ensure waste is effectively sorted and recycled rather than ending up in landfill.

-Materials selected must be compatible and fit for purpose

The solutions or project proposals can cover various TRLs whether it’s a market ready solution or an innovative piece of technology that can help address the issue. For the market ready solutions they would need to go through a trial period on the live network to assess their compatibility.

What are the constraints?

Currently the materials and processes that are in place are to make the networks as cost effective and efficient as possible. This then posses an issue when trying to move away, that may cause costs to increase and reduce the efficiencies in place . Networks primary environmental concerns are typically related to carbon emissions, reliance of fossil fuels and infrastructure degradation rather than plastic waste. Which creates constraints with the adoption of new practices and use of materials, the solutions associated costs must be competitive with existing.

Who are the key players?

Utility companies as a whole are affected by this issue, the problem specifically was introduced by Gas Networks who have slightly different forms of waste to other networks. Specifically gas networks have a large volume of waste on single use fittings, pipe cut offs and single use pipe bypasses. However there are issues that extend to other utilities with various different issues and similarities such as non-recyclable packaging and plastic sheeting.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

N/A

What else do you need to know?

Any further details can be provided on request upon scale of wastage per annum or specific networks waste.

Download full document here

Presentation slides here

Presentation video here

What is the problem?

SP Energy Network have set a Net Zero by 2035 commitment. In line with best practice, we will reduce our emissions by at least 90% and offset residual emissions to reach net zero.

In line with best practice, we will start increasing the number of offsets towards our target date of 2035. We will prioritise carbon removal over carbon avoidance in line with the Oxford Principles for Net Zero Aligned Carbon Offsetting (2024).

In RIIO-T3, we are proposing to develop our offsetting approach to ensure we can mitigate residual emissions in a way which maximises benefit to nature and our local communities, as well as supporting the development of local net zero aligned offsetting markets.

Although there is a mature market for UK based carbon offsets derived from the Woodland Carbon Code and the Peatland Carbon Code, we also need to support local emerging offsetting markets and codes which may not currently be verifiable. These will need to be evidenced using a robust methodology.

The problem is that we do not know the best way to support local emerging offsetting markets, and we need to ensure that any schemes we do support can be evidenced through a robust methodology.

What are we looking for?

- A desk-based review of emerging local offsetting markets and codes which have potential to support our net zero strategy.

- Recommendations for how SPEN can best support local offsetting markets – either on our owned land, within our local communities, or within our wider operating areas

- Support on how we can develop a method for evidencing offsets which may not be currently verifiable.

- Benchmarking exercise to understand what is currently on the market and what is working well

- Cost benefit analysis of solutions

What are the constraints?

The solution must:

- Review local offsetting markets within our operating area which have potential to support our net zero strategy.

- Solutions must align with our Sustainable Business Strategy

- Develop specific recommendations and actions SPEN can undertake to support local offsetting markets in a way that maximises benefit to nature and our local communities AND allows SPEN to credibly offset emissions in line with the Science Based Targets Corporate Net-Zero Standard.

- Consider how local offsetting markets can be evidenced through a robust methodology, which ensures we are not ‘greenwashing’ or wasting money.

Who are the key players?

SPT, SPM, SPD, Local Authorities, Nature Scot, Specialist Companies, Startups, Local Communities.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

In RIIO-T2, we made a Commitment to offset the SF6 emissions where repairs to leaking SF6 assets proved ineffective. To meet this commitment, we purchased UK Pending Issuance Units. These units, when, mature, will compensate for emission in line with our Commitment. We predict we will purchase around 10,000tCO2e by the end of RIIO-T2. This approach also helps to restore biodiversity and benefits local communities who can enjoy new native woodland.

T2 offsetting has increased our knowledge of the carbon market, its maturity and limitations and this has helped us to devise our RIIO-T3 approach as a mix of verified carbon offsets and collaborative market development.

What else do you need to know?

We would expect this study to be tailored specifically to SPEN and to focus on SPEN’s unique position in our local community as a Network Operator.

Download full document here

Presentation slides here

Presentation video here

Maximising Use of Existing Infrastructure

Making the most of the networks' current infrastructure, to reduce the consumer cost and environmental impact associated with new construction projects.

What is the problem?

Monitoring through bolt corrosion in concrete structures, gantries, and switchgear requires either physically removing and replacing the bolts or using the Ultrasonic method. Replacing through bolts, even if they are found to be healthy, incurs an additional cost once they are removed. This results in an economic loss as the healthy bolts are unnecessarily replaced. The condition of through bolts in substations cannot be accurately determined through visual inspection alone. Diagnostic testing is necessary, and while ultrasonic field measurements are a practical option, they have proven to be unreliable and time-consuming due to inadequate procedures and calibration standards. Steel bolts supporting insulators and live conductors have been found suffering severe wastage. Additionally, conducting inspections and repairs for through bolt corrosion currently requires electrical outages.

What are we looking for?

Implementing a cost-effective and non-intrusive method to measure and identify corrosion on through bolts in grid substation concrete structures by avoiding unnecessary bolt removal and replacement. This approach improves asset health, reduces labour costs, minimises outages, and enables timely maintenance. Additionally, successful implementation opens possibilities for wider industry adoption, providing an efficient and cost-effective solution for corrosion detection and maintenance.

What are the constraints?

Existing methods –

- Ultrasonic method – ultrasonic transducers: split pin cause multiple reflection, also need to connect to the bolts. (Unreliable, time-consuming due to inadequate procedures and calibration standards issues, reflection is low amplitude)

- Inspections –Currently requires electrical outages.

- Magnetic Induction measurement- Even if it’s an external intrusive method, need sensors to install outside Laboratory tests failed to record any repeatable linearity.

- Micro-Ohmmeter measurement - Need to clean carefully using rotary abrasive pad.

Insufficient space at each end of the bolt to locate 4 measurement connectors (2 to pass current and 2 to measure voltage)

Who are the key players?

Identifying a non-intrusive method for corrosion inspection would benefit Electricity Distribution, Electricity Transmission, Electricity System Operator, Gas Distribution, Gas Transmission. Corrosion is a significant issue across various industries, leading to economic losses. It would be valuable to explore innovative methods used in other industries, particularly in offshore oil and gas sectors, considering the importance of achieving net-zero goals and the influence of future offshore technologies. Additionally, this problem is specific to NGET, and key stakeholders have shown interest in finding a solution.

- Asset Operations Team

- Healthy and safety officers

- Maintenance Team

- Electrical Engineers

- Civil structure engineers

- Substation Engineers

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

Yes, this problem statement builds on existing infrastructure and anticipated policy decisions related to asset management and maintenance practices. It connects to previous innovation projects focused on non-intrusive monitoring and corrosion management. Current dependencies include the need for reliable diagnostic testing methods and compliance with safety regulations. Innovators should reference ongoing initiatives in corrosion monitoring and asset integrity management, as well as relevant industry standards. While solutions like ultrasonic testing have been trialled, their effectiveness has been limited, indicating a need for improved methodologies. Exploring successful case studies in related sectors may also provide valuable insights for new proposals.

What else do you need to know?

To submit a proposal for this problem statement, innovators should understand the challenges of through bolt corrosion, including the economic impact of unnecessary replacements and the limitations of current monitoring methods. They should review relevant literature, familiarize themselves with the network's asset management processes, and identify any technological advancements or funding opportunities. Engaging with key stakeholders will also provide valuable insights to support their proposals.

Download full document here

Presentation slides here

Presentation video here

What is the problem?

Almost 70% of NGET’s cable assets are non-XLPE cables. These cables were installed between the 1970s and 1990s, and they are expected to reach the end of their life within the next 20 to 40 years. The plan is to eventually replace all these non-XLPE cables with XLPE cables. There are a few risks that NGET might face in the meantime.

One of the risks is related to the availability of experienced workforces. As the younger generation may not be interested in becoming experts in a technology that is becoming obsolete, there is a concern about having enough skilled personnel to maintain and operate the non-XLPE cables until they are replaced.

Another problem is the uncertainty around the sustainability of the supply chain for these old technologies. With the emergence of new XLPE cables that offer higher quality and lower production costs, there is a higher demand for XLPE cables. This may lead non-XLPE manufacturers to cease production of their older cable technologies and shift their production line to XLPE cables. As a result, the availability and reliability of a solid supply chain for non-XLPE cables is unknown for NGET.

Even if there is any plan to face cables obsolescence crisis, the optimum timing of its execution to minimise the cost and risk to the grid is unknown.

What are we looking for?

NGET is looking for a solution to identify the early signs of cables and their accessories obsolescence at their early stage so it can proactively develop a plan to determine an appropriate timeline to mitigate the potential challenges. The objective is to stay ahead of the curve and ensure that necessary measures are taken in a timely manner to address the obsolescence of cables and their associated components effectively.

This project is expected to start at TRL3 and is increased to TRL6+.

What are the constraints?

To ensure the reliability and accuracy of any proposed method for detecting early signs of obsolescence, it is important to include a verification procedure to any proposal. This verification procedure serves as a critical step to validate the effectiveness and robustness of the detection method.

Who are the key players?

The key stakeholders of this project are cable asset management and procurement teams in TSOs and DSOs.

It is expected that a multidisciplinary team of experienced cable engineers, supply chain specialist, data scientist, market analyst and strategist are required to address this problem.

Does this problem statement build on existing or anticipated infrastructure, policy decisions, or previous innovation projects?

This is a novel problem, and no work has been previously done in this field.

Download full document here

Presentation slides here

Presentation video here